Digital Manufacturing at the speed of business

From idea to production, Stack3D is fully integrated to meet your personalized, flexible additive manufacturing needs. From custom material development to prototyping to small-scale production, we partner with you to meet your unique material and application challenges!

3D Printing Services

Idea to Prototype to Production

Our team has 60+ collective years in the use of Additive Manufacturing technology! We provide on-demand 3D printing from idea to prototype to production in as fast as 1-2 days. Get an instant 3D printing quote today through our digital quoting platform, and work with our experienced team to help you achieve the full potential of additive manufacturing.

Additional Services & Capabilities

Additive Manufacturing Technologies

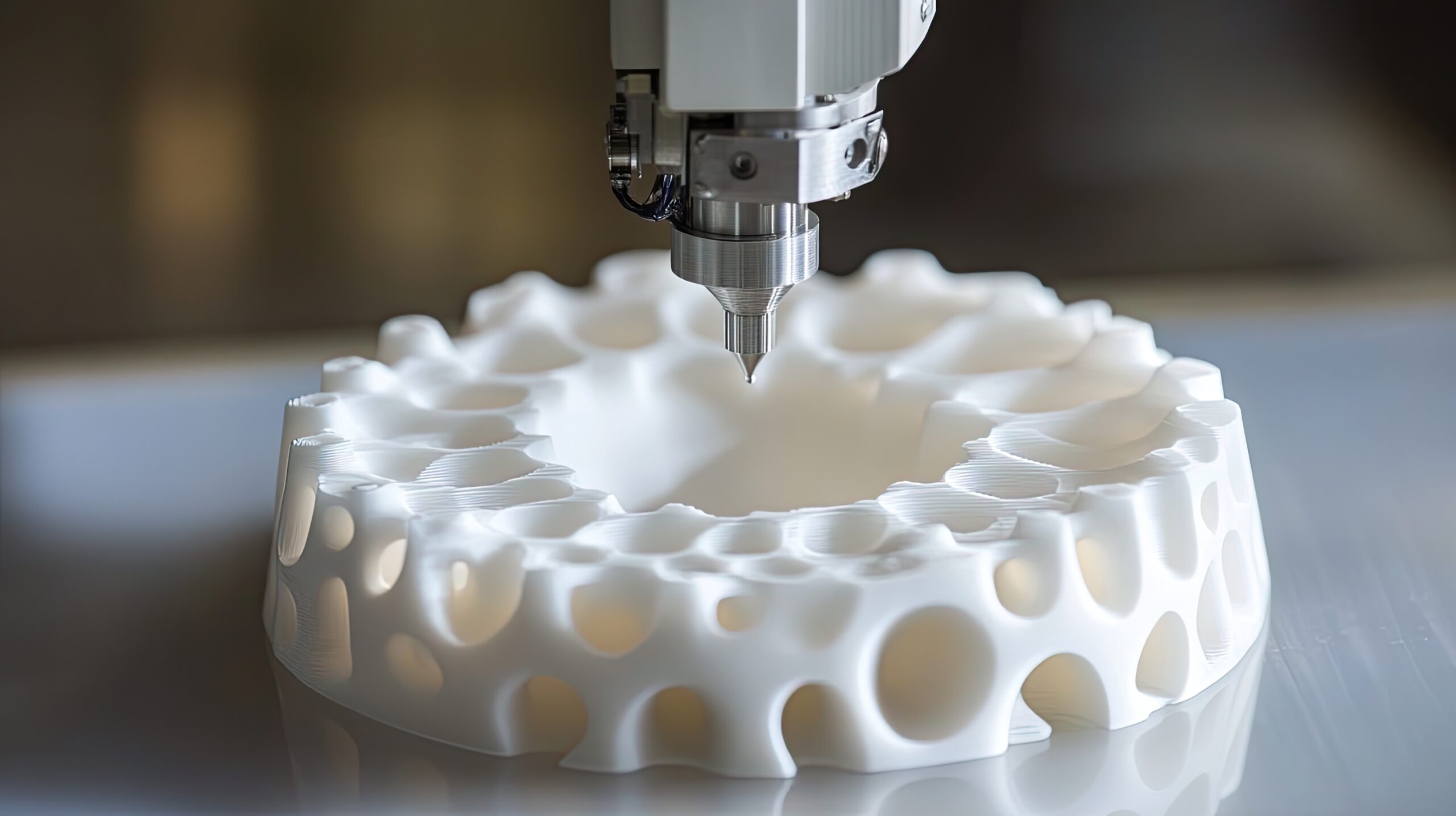

SLS

Selective Laser Sintering (SLS) gives you the freedom to create intricate, high-quality parts with unmatched precision. SLS parts tend to be very durable with excellent surface characteristics.

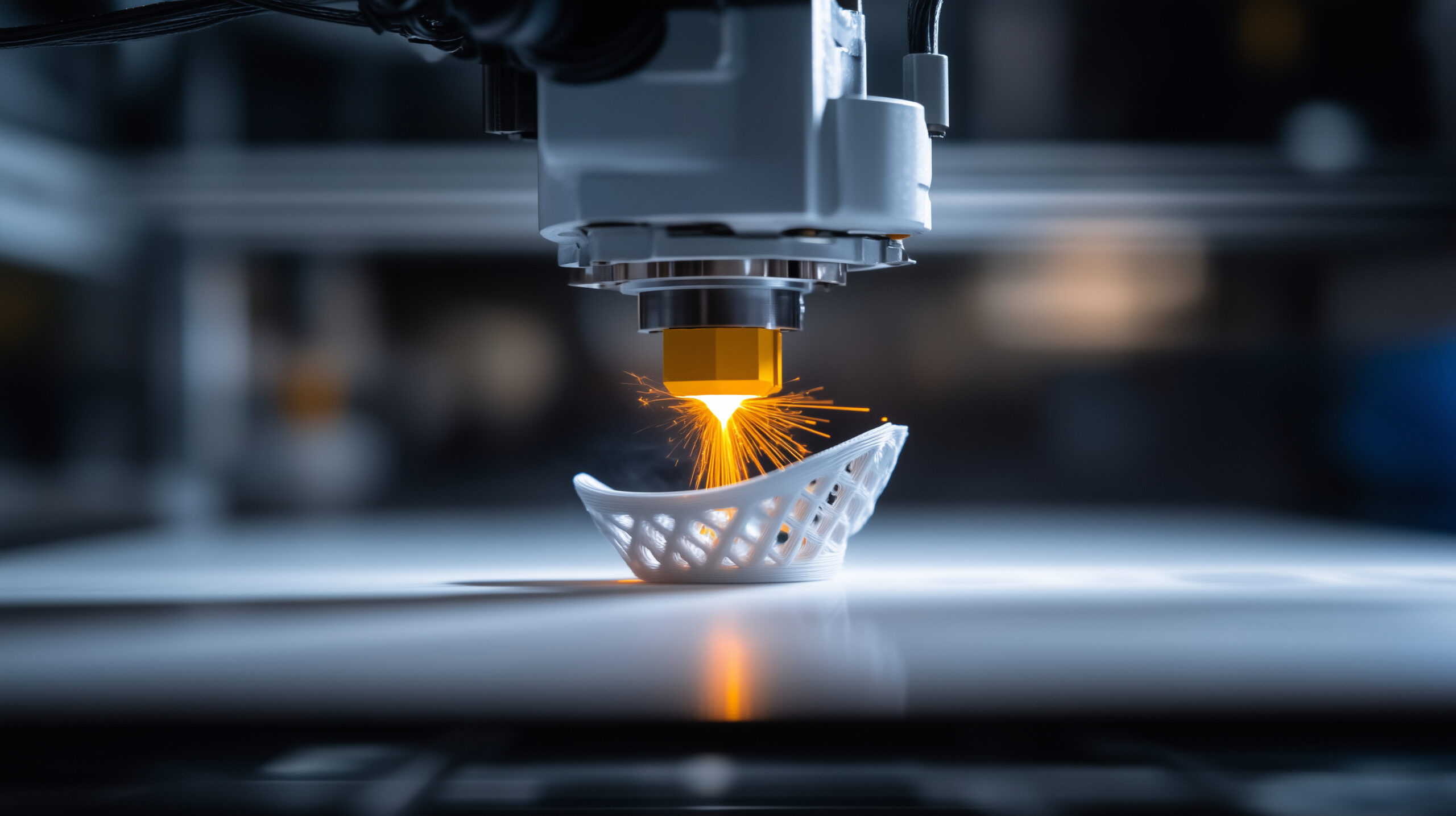

FDM

Fused Deposition Modeling (FDM) parts tend to be tougher and more robust than other additive technologies. That makes them ideal for demanding applications like jigs and work-holding fixtures.

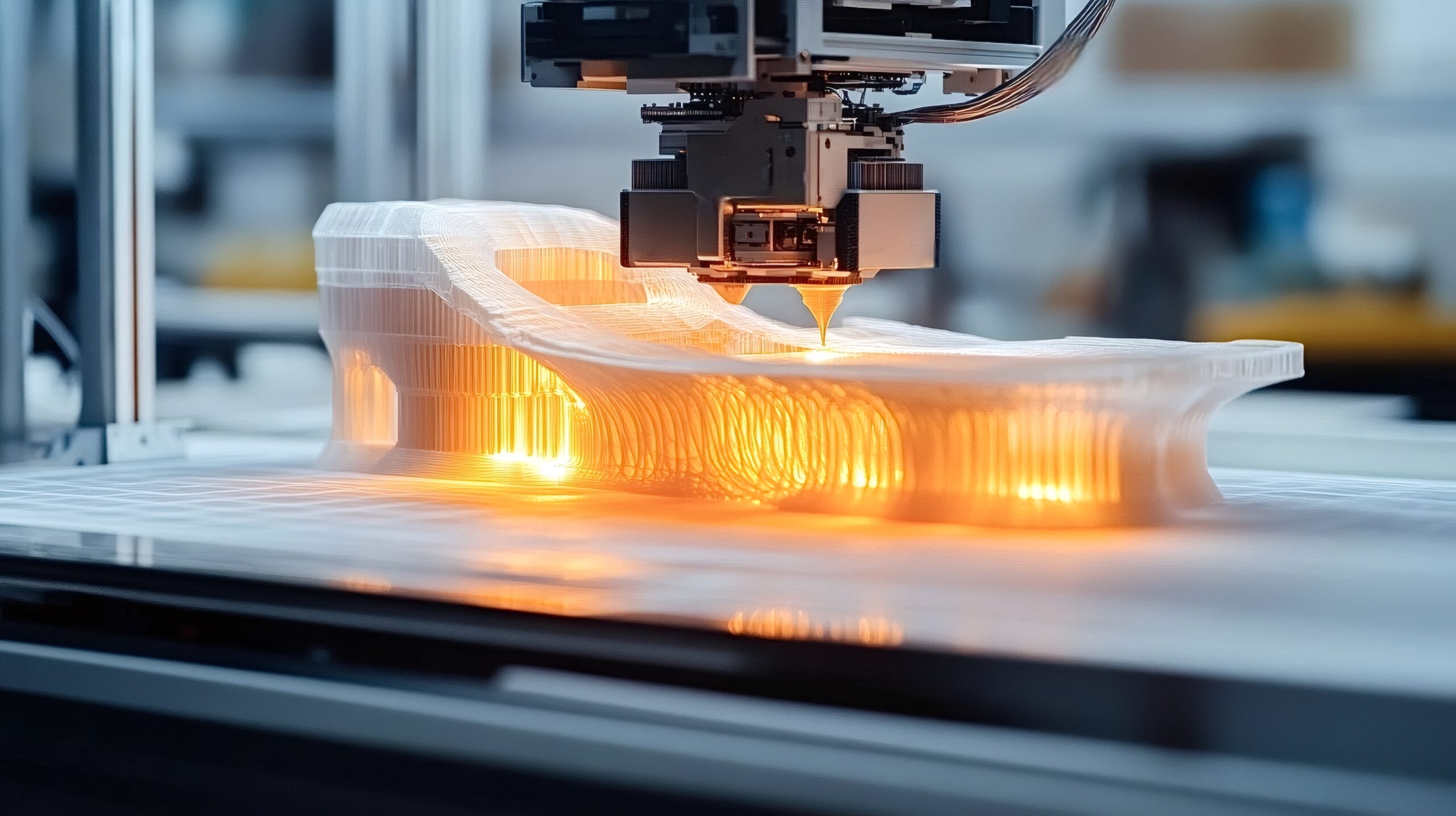

LFAM (COMING SOON)

Large format additive manufacturing (LFAM) is used for large, complex geometries and reducing multipart assemblies into a single design. We can print parts as large as 3m x 2m x 2m.

Materials Expertise in the Additive Manufacturing Industry!

Production of Non-Standard Materials, Including Custom Colors

We easily match a stock material to your application requirements when you make the request. But what happens when standard material library options do not fulfill the application need? Our competitors may not have the answer or the solution. We do. Stack3D has the capability to manufacture non-standard feedstock filaments and pellets. This includes the development and production of custom color filament and pellets. We do all of this with short lead times and at a resonable cost.

Contact Us

Passionate – Dedicated – Professional